Manufacturing the donkey cart and ambulance

Practical Action

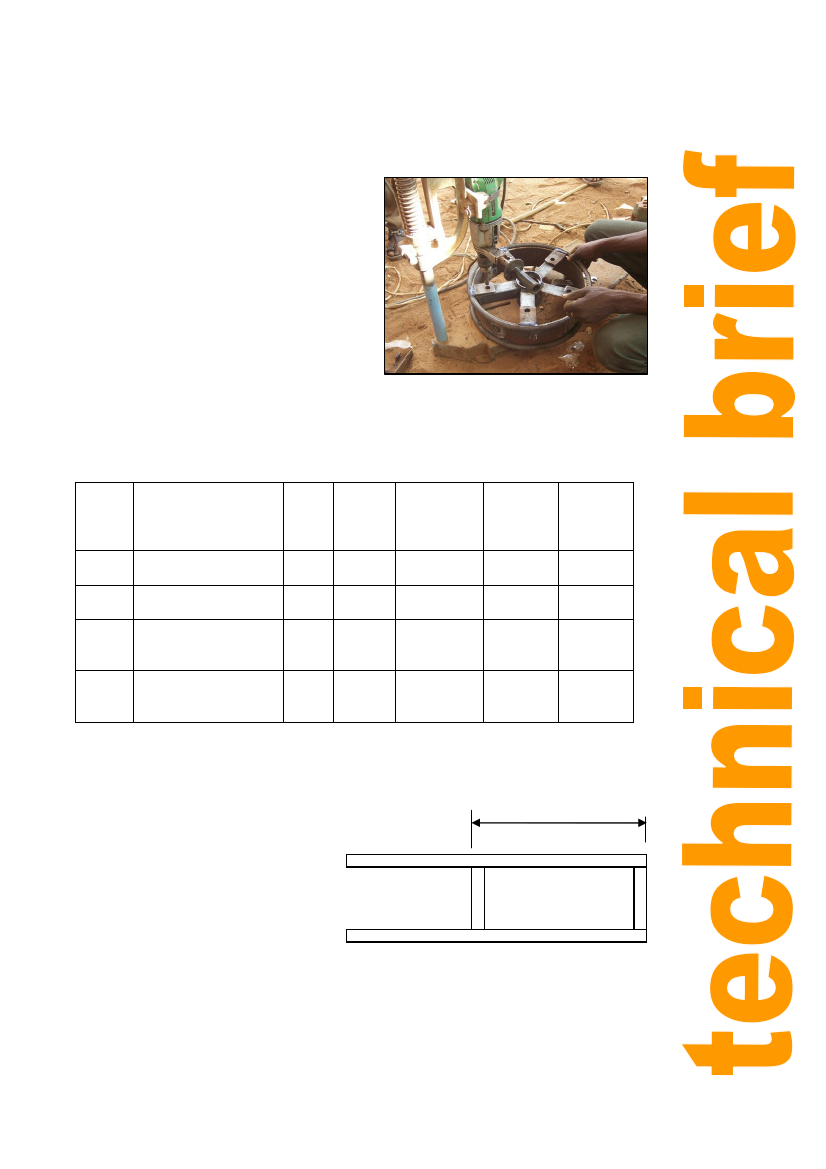

13. Next the 12 mm clearance holes in part E need to be extended into the

spokes. This can be done using a drill following the path of the holes in the tabs

(see pic 10).

14. Following this all parts need to be

deburred and left in a good condition

ready to be painted. The 12 mm bolts are

used to connect the spokes and the tabs

for extra strength and support. The wheels

can be painted and once dry the bearings

can be fitted.

60 mm

15. Finally suitable sized tires can be

pressed onto the wheels.

4. Manufacturing the Frame

Picture 10: A makeshift piller drill used

for drilling the holes in the spokes

4.1. Parts List

Part Material and Notes

No

off

A Mild Steel Tube

2

(main frame)

B Mild Steel Tube

2

(main frame)

C Mild Steel Right

2

Angle Section (sub

frame)

D Mild Steel Right

4

angle section (sub

frame support strap)

Length

(mm)

3000

Width or

cross

section

(mm)

550

1350 50 x 50

700 25.4 x

25.4 (1')

Depth /

Wall

Thicknes

s (mm)

1.5

1.5

3

Diameter

(mm)

External

50.8 (2')

External

50.8 (2')

1.5

4.2. Instructions

1. Hammer the ends of parts A and

B so they are oval in shape and

arrange them as in the diagram

(right) and weld in place.

Diagram 7. Plan view of frame

1800 mm

2. The next part to be made is the

axle support frame (part 3). Using

a hacksaw cut the angle iron along

the 6 dotted lines shown in

diagram 8 (Dimensions in mm).

8